—

Our car floor mats are vacuum-formed, ideal for large-size coverage, waterproof performance, and cost efficiency.

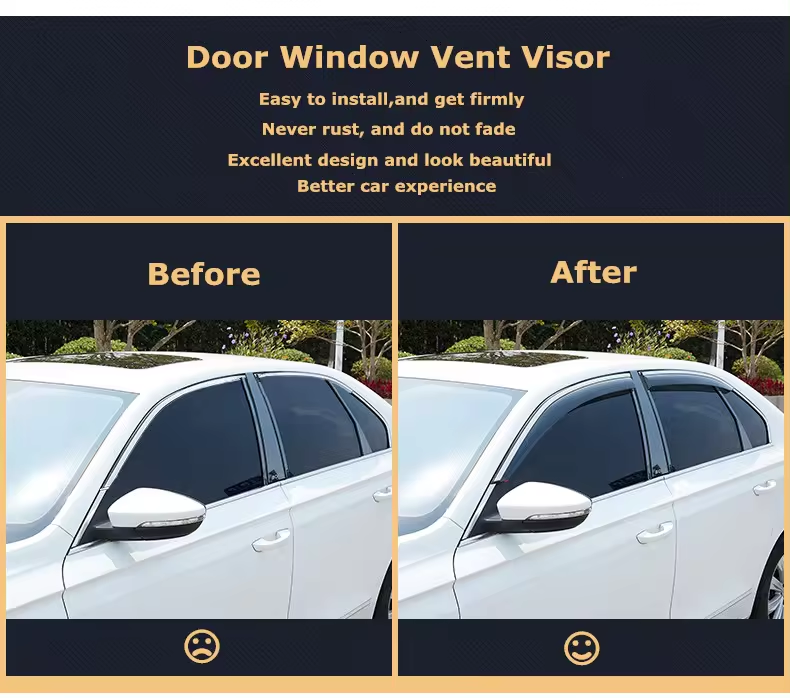

1. Window Visors — Injection Molding Technology

Our window visors are produced using injection molding, which ensures:

High strength and durability

Perfect fit with precise molding

Smooth surface with excellent transparency

Strong resistance to deformation and cracking

OEM-level finish and consistent quality

Technology: Injection Molding

Production Method: Injection Molded

Material Options: PMMA / PC

2. Floor Mats — Vacuum Forming Technology

Our TPE/5D car floor mats are made with vacuum forming, ideal for large-size coverage and all-weather use:

One-piece large-area forming

Lightweight, waterproof, and easy to clean

Raised edges and 3D high-wall protection

Cost-effective for mass production

Flexible MOQ and stable quality

Technology: Vacuum Forming

Production Method: Vacuum Formed

Material Options: TPE / TPE + XPE

3. Why We Use These Two Different Methods

Injection molding is perfect for window visors because it offers high precision, transparency, and strong durability.

Vacuum forming is ideal for floor mats because it supports large surface shaping, high walls, and cost-efficient production.

Each process is chosen to provide the best performance for the specific product.

TPE 5D Car mat:

window deflector:

Wechat / WhatsApp:+86 153 2512 9500